ASHVILLE, NC—What happens when you take a couple of bike-geek

engineers accustomed to making precision robotics, high-end golf clubs and

medical equipment in a multi-million-dollar manufacturing facility and set them

loose designing bike components? In the case of Industry Nine, a new Asheville, North

Carolina, based components company, those engineers took a modest shot at

reinventing the wheel.

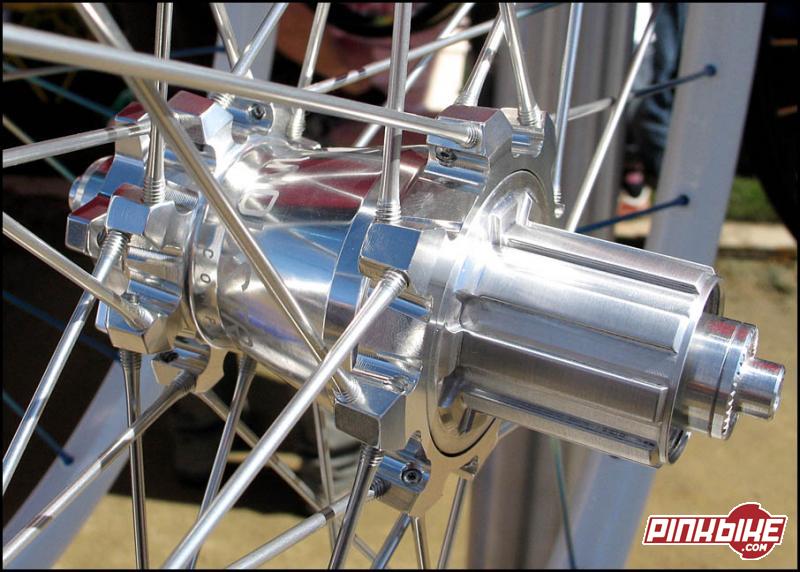

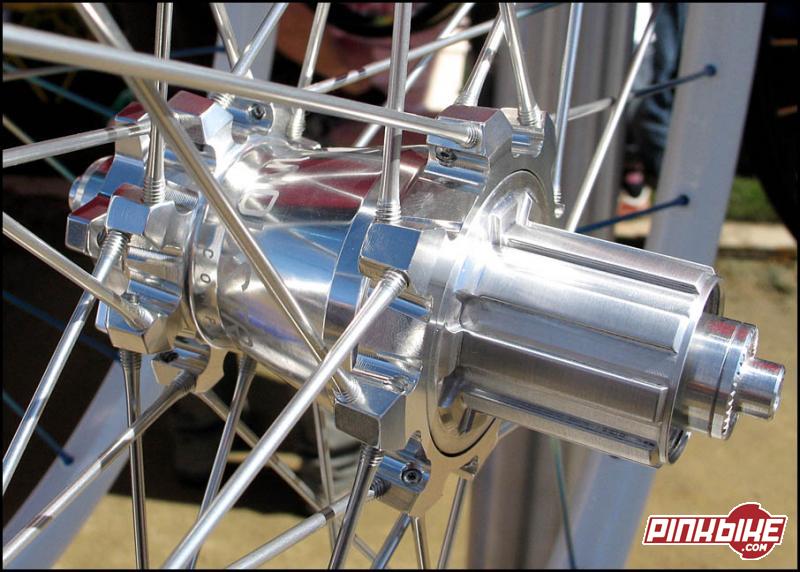

Industry Nine debuted at

Interbike last year with its unique new wheel design featuring an integrated

spoke-and-nipple design machined from a solid rod of 7075 T-6 aluminum. The

spokes thread directly into Industry Nine’s proprietary hub and can be used with

any 32-hole rim. Wheels can be trued with conventional spoke wrenches courtesy

of machined-in wrench flats on the nipple ends.

The bottom line for the rider is

fewer parts and—because it’s all aluminum—a lower rotational mass than even some

top competitors. In layman’s terms, that means you accelerate faster. The

process of milling each spoke from a solid bar of extruded aluminum takes about

two minutes per spoke on a quarter-million dollar lathe.

Industry Nine product manager

John Kiffmeyer said that using 32 spokes, laced to your choice of rim in a

tried-and-true two-cross pattern, makes the company’s wheels stronger than

comparably priced wheels that use forged aluminum spokes with a low-spoke-count,

direct-pull lacing pattern. The company offers stock price-point

wheelsets built with DT Swiss hoops in All-Mountain, Enduro, FR/DH, 29er and

Single Speed variations in three standard colors: anodized black, sliver or red.

Road and BMX wheels are in the works.

But don’t feel hampered by the

stock offerings—at Industry Nine customization is king. Spoke gauge, length and

spoke and hub color all can be made to order. Industry Nine’s

patent-pending spoke design is just part of the new company’s story. The company

is also waiting on a patent for a new freehub body drive mechanism that it

designed from the ground up. (Kiffmeyer said the company isn’t posting pictures

of the internals until the patent clears, so to see how one in action you have

to buy a rear hub and crack it open.)

The drive mechanism uses three or

six pawls, depending on preference, for engagement every six or three degrees of

rotation, respectively.

Whether the hub is set up with

the three- or six-pawl option, it is designed to only have three pawls engaged

at any given point. In addition to the hub’s quicker-than- average engagement,

each pawl has three engagement ridges, so there are always nine simultaneous

points of engagement. To ensure that all those tiny engagement points

stand up to even the angriest pedal mashers, the pawls and engagement ring are

cut from A-2 tool-grade steel with a process called Wire EDM (Electrical

Discharge Machining), an electrical erosion process that precision cuts

already-hardened steel to a tolerances within .0001 of an inch. Industry

Nine hubs have hardened stainless steel endcaps and 7075 aluminum hub shells and

axles. Freehub bodies are made from 7068 aluminum, an alloy with tensile

strength 25 percent greater than 7075. Wheelsets come with quick release or

thru-axle options, and the company now offers hub options for Cannondale Lefty

and Maverick fork users.

The only components the company

doesn’t fabricate on its own are rims and Japanese-made cartridge bearings—front

hubs get two, rear hubs get four. All that precision machining will set

you back about $850 per wheelset—a price point comparable to other

aluminum-spoked wheelsets but well worth it in terms of performance and the

ever-important “bling” factor. “We’re very aware of how important look

is, and we went for a modern, clean and graphically appealing product to

bring some color and excitement back into the wheel market,” said Kiffmeyer. “I

want the customer to say, ‘I know it’s strong, I know it’s fast, but damn it

looks good.’” Since its Interbike debut Industry Nine has been steadily

ramping up production and distribution. Along with road and BMX wheels, the

company is working on a new line of stems and seatposts.

“We’re thrilled with how well

it’s been received,” said Clint Spiegel, the company’s co-designer and vice

president of its 120-employee parent company Turnamics, an Ashville, North

Carolina, based design and manufacturing shop. Industry Nine shares some

resources with the parent outfit but now has four full-time employees of its

own. Spiegel said he has worked with high-end golf products, tactical

knives, robotics and industrial packaging machinery and has never met with such

a positive initial reception. “The buzz and excitement level in the

industry”—bicycles are his ninth—“have been great.” To find out more

about the company visit its Web site at www.industrynine.net(flash required) or

call them at (800) 404-1775.

Group shot caption: (L to R) John

Kiffmeyer, project manager; Fred Schuldt, production manager; Jeff Baucom,

national sales manager; Clint Spiegel, vice president, Turnamics

Industry Nine Gallery

engineers accustomed to making precision robotics, high-end golf clubs and

medical equipment in a multi-million-dollar manufacturing facility and set them

loose designing bike components? In the case of Industry Nine, a new Asheville, North

Carolina, based components company, those engineers took a modest shot at

reinventing the wheel.

Industry Nine debuted at

Interbike last year with its unique new wheel design featuring an integrated

spoke-and-nipple design machined from a solid rod of 7075 T-6 aluminum. The

spokes thread directly into Industry Nine’s proprietary hub and can be used with

any 32-hole rim. Wheels can be trued with conventional spoke wrenches courtesy

of machined-in wrench flats on the nipple ends.

The bottom line for the rider is

fewer parts and—because it’s all aluminum—a lower rotational mass than even some

top competitors. In layman’s terms, that means you accelerate faster. The

process of milling each spoke from a solid bar of extruded aluminum takes about

two minutes per spoke on a quarter-million dollar lathe.

Industry Nine product manager

John Kiffmeyer said that using 32 spokes, laced to your choice of rim in a

tried-and-true two-cross pattern, makes the company’s wheels stronger than

comparably priced wheels that use forged aluminum spokes with a low-spoke-count,

direct-pull lacing pattern. The company offers stock price-point

wheelsets built with DT Swiss hoops in All-Mountain, Enduro, FR/DH, 29er and

Single Speed variations in three standard colors: anodized black, sliver or red.

Road and BMX wheels are in the works.

But don’t feel hampered by the

stock offerings—at Industry Nine customization is king. Spoke gauge, length and

spoke and hub color all can be made to order. Industry Nine’s

patent-pending spoke design is just part of the new company’s story. The company

is also waiting on a patent for a new freehub body drive mechanism that it

designed from the ground up. (Kiffmeyer said the company isn’t posting pictures

of the internals until the patent clears, so to see how one in action you have

to buy a rear hub and crack it open.)

The drive mechanism uses three or

six pawls, depending on preference, for engagement every six or three degrees of

rotation, respectively.

Whether the hub is set up with

the three- or six-pawl option, it is designed to only have three pawls engaged

at any given point. In addition to the hub’s quicker-than- average engagement,

each pawl has three engagement ridges, so there are always nine simultaneous

points of engagement. To ensure that all those tiny engagement points

stand up to even the angriest pedal mashers, the pawls and engagement ring are

cut from A-2 tool-grade steel with a process called Wire EDM (Electrical

Discharge Machining), an electrical erosion process that precision cuts

already-hardened steel to a tolerances within .0001 of an inch. Industry

Nine hubs have hardened stainless steel endcaps and 7075 aluminum hub shells and

axles. Freehub bodies are made from 7068 aluminum, an alloy with tensile

strength 25 percent greater than 7075. Wheelsets come with quick release or

thru-axle options, and the company now offers hub options for Cannondale Lefty

and Maverick fork users.

The only components the company

doesn’t fabricate on its own are rims and Japanese-made cartridge bearings—front

hubs get two, rear hubs get four. All that precision machining will set

you back about $850 per wheelset—a price point comparable to other

aluminum-spoked wheelsets but well worth it in terms of performance and the

ever-important “bling” factor. “We’re very aware of how important look

is, and we went for a modern, clean and graphically appealing product to

bring some color and excitement back into the wheel market,” said Kiffmeyer. “I

want the customer to say, ‘I know it’s strong, I know it’s fast, but damn it

looks good.’” Since its Interbike debut Industry Nine has been steadily

ramping up production and distribution. Along with road and BMX wheels, the

company is working on a new line of stems and seatposts.

“We’re thrilled with how well

it’s been received,” said Clint Spiegel, the company’s co-designer and vice

president of its 120-employee parent company Turnamics, an Ashville, North

Carolina, based design and manufacturing shop. Industry Nine shares some

resources with the parent outfit but now has four full-time employees of its

own. Spiegel said he has worked with high-end golf products, tactical

knives, robotics and industrial packaging machinery and has never met with such

a positive initial reception. “The buzz and excitement level in the

industry”—bicycles are his ninth—“have been great.” To find out more

about the company visit its Web site at www.industrynine.net(flash required) or

call them at (800) 404-1775.

Group shot caption: (L to R) John

Kiffmeyer, project manager; Fred Schuldt, production manager; Jeff Baucom,

national sales manager; Clint Spiegel, vice president, Turnamics

Industry Nine Gallery

손님

손님

댓글 달기