Electron_shell_004_Beryllium_-_no_label

Beryllium

depositphotos_3091230-Beryllium---Periodic-Table-of-Elements

http://en.wikipedia.org/wiki/Beryllium

M16.JPG

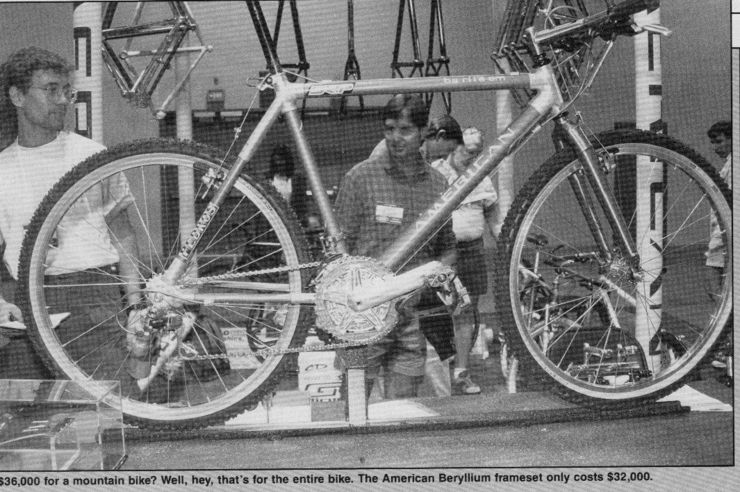

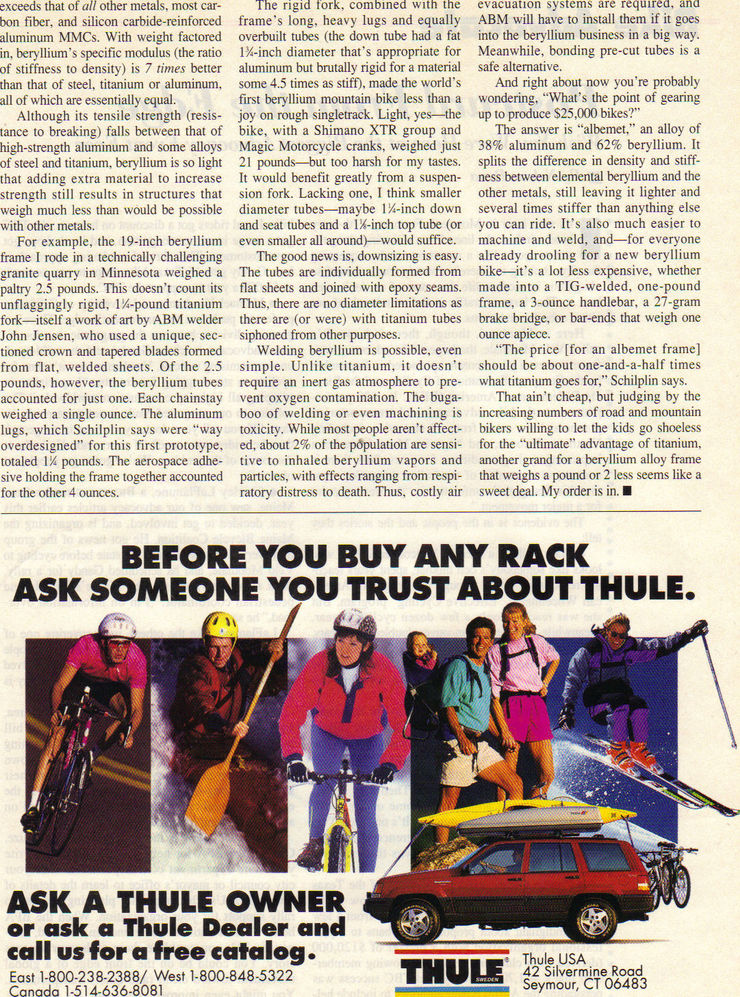

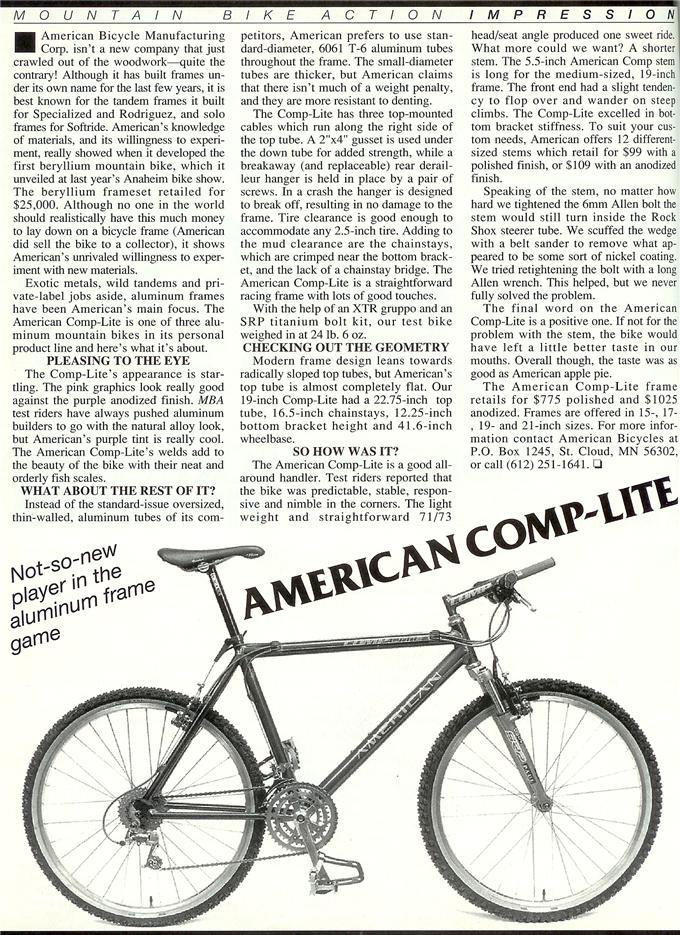

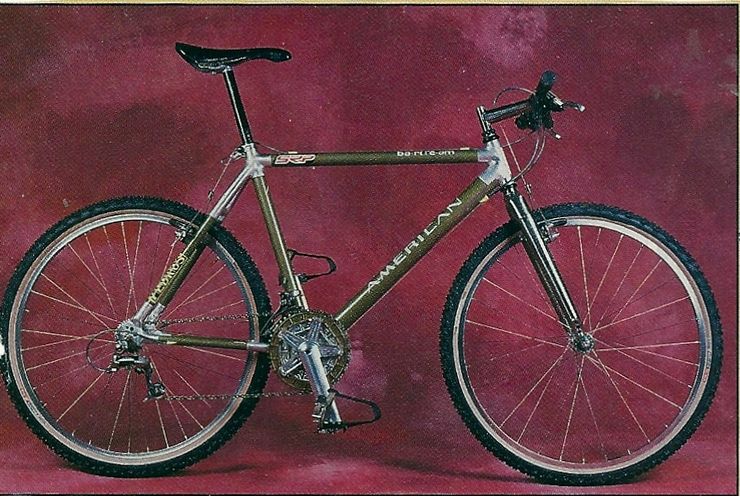

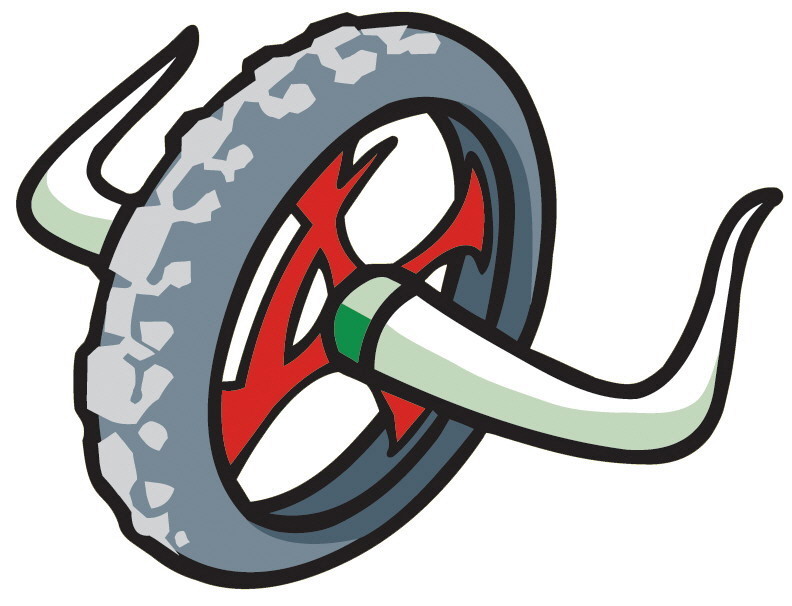

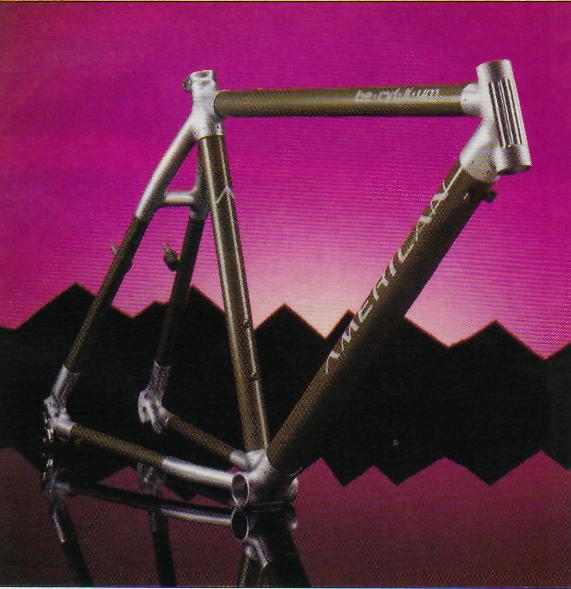

1993: Models are listed as the new M-15 (15" stays?) frame for $720, M-16 or Comp Lite frame @ $925 and the new Comp Lite Beryllium for the astonishing sum of $26,000.

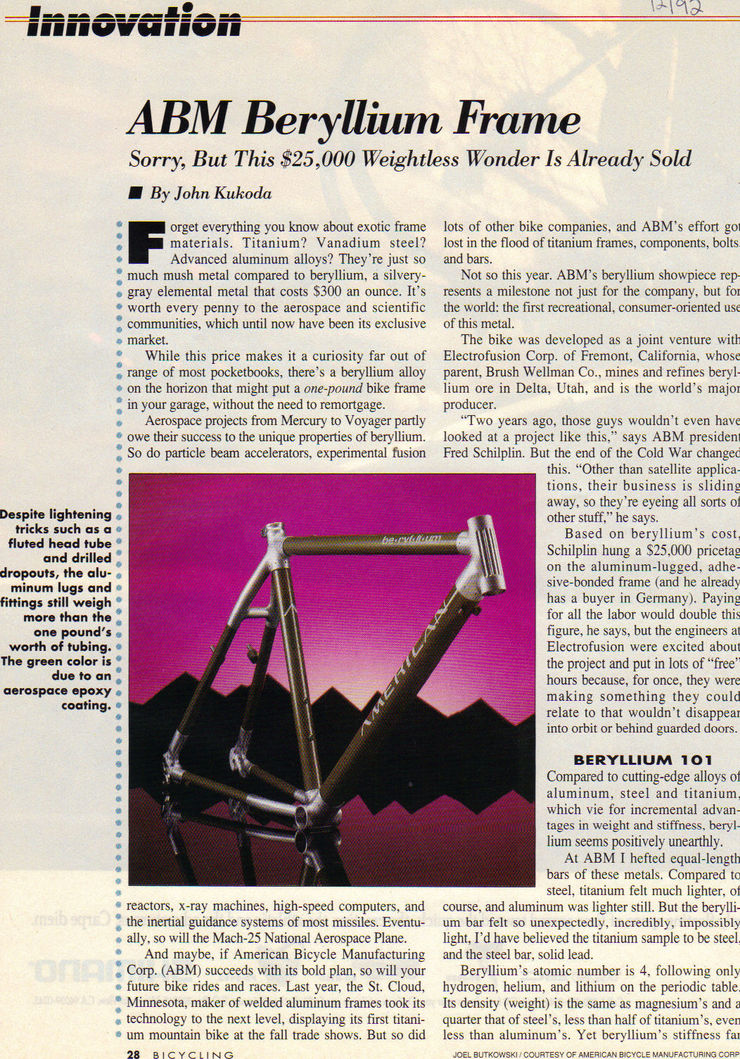

The Beryllium bike was made with Beryllium tubing (top, seat, down, seat stays, chain stays)

"bonded into aluminum lugs".

193AmericanBer.jpg

The bike was developed with Electrofusion Corp. in Fremont California.

Much of the labor was donated by the company since there was some spare time due to the decline in "Cold War business for the company".

Beryllium's atomic number is 4 just after Hydrogen, Helium and Lithium but the specific modulus (stiffness to density ratio) is seven times better than steel, titanium or aluminum, which are all essentially equal.

The first frame was overbuilt and weighed 2.5 pounds.

Of that, the Beryllium tubing was one pound (including one ounce chain stays), 1.25 pounds of aluminum lugs and 4 ounces of adhesive.

Beryllium Aluminium alloys are a bit less toxic, the real handicap is the price tag which on the American market for vacuum-cast beryllium ingots was about $338 per pound ($745 per kilogram) in 2001. That's was about 20 times the price of titanium ingots at the time. Processed into tubing, it would be signifcantly more expensive.

Aluminium Lithium alloys are a better venture to look into (aka 8000 series alloys), being about 10% lower density and 15% greater stiffness. Its been extensively used in aviation and space vehicles for a couple decades now. The current shuttle external tank is primarily Al-Li alloy construction.

"This bike is made of a space age metal matrix material called Boralyn.

Boralyn is a 6000 series aluminum thats impregnated with millions of tiny Boron-Carbide particles (B4C).

Based on the particles used the properties of the metal changes.

Univega uses a combination that gives the bike the strength of Titanium but the lite weight and stiffness of Aluminum.

Apparently they stopped making them cause they where too hard and expensive to manufacture ."

Univega's Boralyn tubeset... it was a boron-carbide enhanced aluminium alloy class known as an MMC. The original Specialized M2 Stumpjumpers were also using an MMC, except silicon-carbide based as memory serves. Generally MMC's are stiffer and stronger than a comparable density of Aluminium alloy, but the surface hardness is also a lot higher. Butting the tubesets and milling the ends to make a frame is absolutely murder on the tooling. That's why except for the final year or two of M2 frames were all straight gauge tubing (and in the end only the seattube got any butting) and they never extended the material to any other model.

American Bicycle Manufacturing made a total of FOUR of those frames, and one was stolen out of their wharehouse. The other three sold to people at tradeshows (I believe Taipei, Interbike-Annaheim, and Eurobike-Frankfurt). The frame was bonded together, and weight 2.5 pounds for an 18" size. The Be tubes were pure beryllium, and totaled a pound of tubing. The Al lugs and the epoxy were another 1.5 pounds. They cost about 20k each in 1992 dollars.

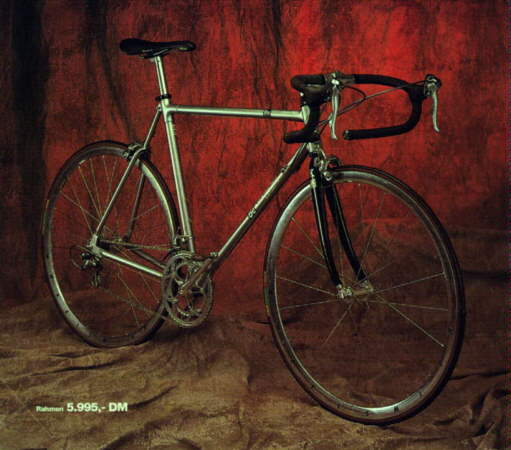

In the mid-90s after the breakup of the USSR and the decommisioning of a large number of their nuclear submarine fleet, a company called Be-Yond Fabrications offered Be/Al alloy frames with complete bike prices (with XT parts) around $7000. They used scrap tubing from the subs.

http://www.lightmetalage.com/covers.php?DisplayPage=25

cover_1999_04_sm.jpg

1992AmericanBe1.jpg

berilium frame.JPG

1992AmericanBe2.jpg

1093AmericanCL.jpg

BeYOND Be401 Beryllium MMC Road.JPG

american_beryllium_bike.jpg

관리에 대해선 참 낭설이 많았던 프레임이고 합니다.

라이딩 시 탑튜브에 땀이 떨어지면 연기와 함께 불꽃이 튀긴다는 등...ㅋ

MOMBAT/BikeHistoryPages/American.html

출처...MOMbat

손님

손님

댓글 달기